Imagine,

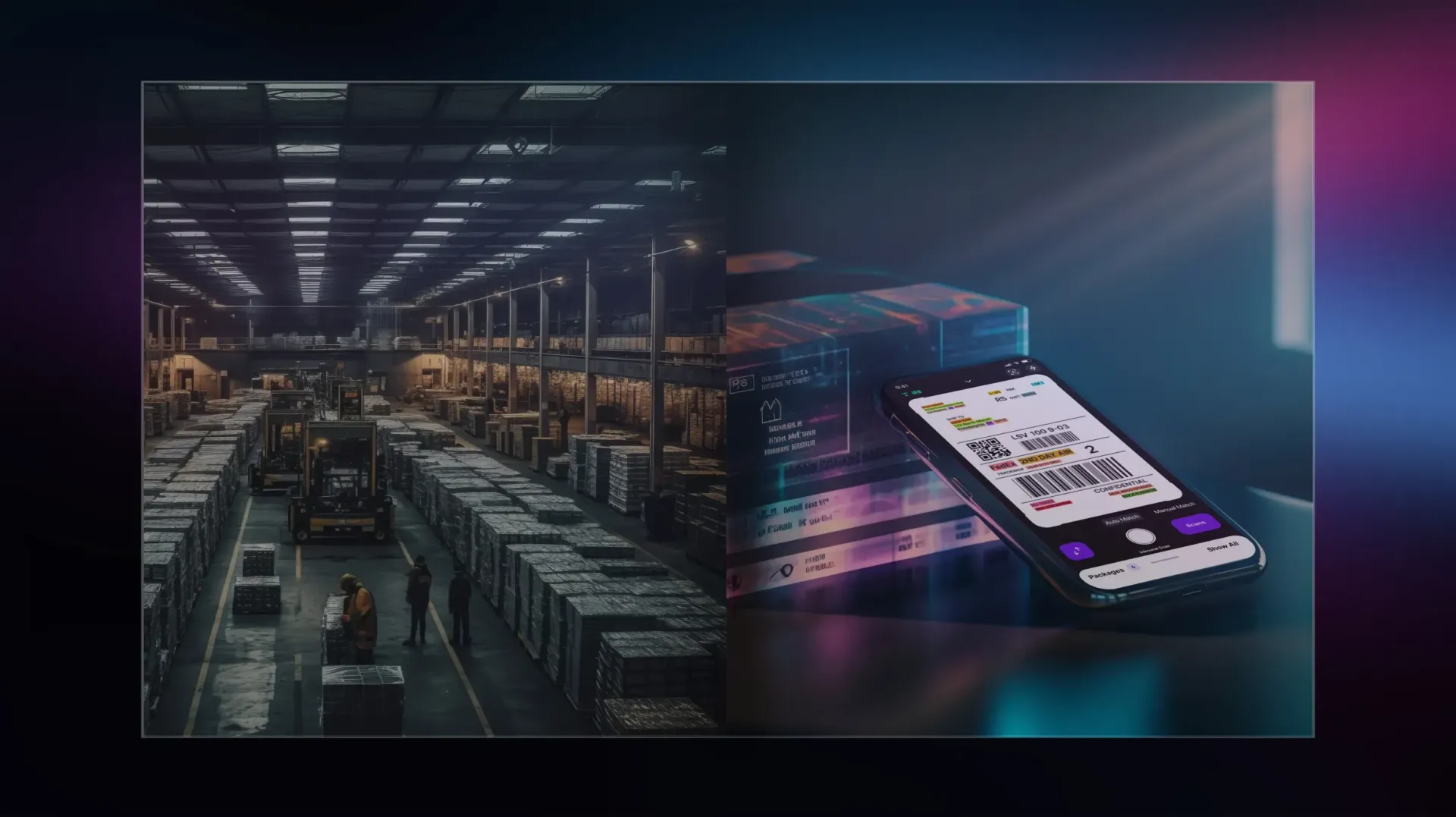

a world where your package is picked, packed, and delivered with lightning speed and precision — all without any human intervention.

Discover,

how, cutting-edge technologies, can help you to automate logistics process.

Enhance,

the effectiveness of your logistics operations with dedicated solutions from 3S.

Unlock the Power of Logistics Automation: Rethink Supply Chain

In today’s fast-paced digital landscape, efficient and streamlined logistics operations are vital for success. By automating various aspects of your logistics processes you can save time, reduce costs, and enhance customer satisfaction. Automation in logistics is improving logistics operations with software that handles a fraction of human-managed processes or the machinery that takes over a part of manual tasks.

Learn how 3S can support your business with dedicated solutions to logistics automation.

Learn how we can assist you to delve into the key objectives your business can achieve with logistics automation, address the challenges you may encounter, select a logistics automation system, provide best practices to implement, and offer actionable insights to optimise your operations.

Automation in Incoming Goods

When incoming goods are marked with barcodes, it automatically notifies the automation system of their arrival. This helps in the scanning and proper identification of goods, which further ensures correct quality assessment and handover to the fixed machinery in the warehousing or distribution unit. It will help your system assign the goods to the appropriate conveyors, cranes, sortation systems, or storage shelves.

Automation in Dispatching

When the logistical functions are automated end-to-end, your automation system can efficiently assign outbound goods to appropriate dispatch units and outgoing stocks. Not only does this optimise the tasks undertaken by machines, but it can also reduce human efforts and costs.

Automation in (Re)Packaging

Automation in process logistics can help expedite packaging and repackaging processes, thus saving your company plenty of cash in human labour costs.

Automation of Goods Retrieval

Your automation system can automatically locate and retrieve specific goods from your inventory when an order is received. It can then set up the product for shipment and delivery.

Workforce Reduction

Automating logistics functions can reduce your workforce by a huge margin. Human input throughout your facilities and the product life cycle can be restricted to only a few critical decision-making tasks. At the same time, the grunt work is undertaken by the automation systems. Further, a network of smaller automation systems can be put in place to make the entire supply chain of logistical functions work smoothly.

Our methodology

Wish to unlock the full potential of streamlined and efficient logistics operations? This is how we work:

01.

Assessing Current Processes:

Begin with assessing your existing logistics processes to identify areas that can be automated. Evaluate your order fulfillment, inventory management, warehouse operations, shipping, and other relevant processes. This assessment will help you understand where automation can bring the most significant benefits.

02.

Defining Automation Goals:

Clearly define your automation goals based on the objectives you aim to achieve. Determine the specific areas or tasks you want to automate, such as order processing, inventory tracking, or shipment notifications. Set measurable goals that align with your overall business objectives.

03.

Selecting Automation Technologies:

Research and select the automation technologies that best fit your business needs. This includes choosing software platforms, hardware systems, and intelligent algorithms that align with your automation goals. Consider factors such as scalability, integration capabilities, ease of use, and compatibility with your existing systems.

04.

Integrating Systems:

Ensure seamless integration between your existing systems and your selected automation technologies. This may involve integrating your e-commerce platform, warehouse management system (WMS), inventory management system (IMS), and other relevant systems with automation software and hardware. The integration enables data flow and ensures a smooth end-to-end automation process.

05.

Implementing Automation:

Develop a detailed implementation plan that outlines the steps and timeline for deploying the automation technologies. This includes configuring the software, setting up hardware components, and testing the system for functionality and reliability. Conduct thorough training sessions to familiarise your team with the new automation processes.

06.

Monitoring and Optimising:

Continuously monitor the performance of your logistics automation system to identify areas for improvement. Collect and analyse data on key e-commerce metrics such as order processing time, inventory accuracy, and shipment efficiency. Use this data to optimise your automation workflows, make necessary adjustments, and drive ongoing improvements.

07.

Employee Training and Support:

Provide comprehensive training and support to your employees to ensure they can effectively work with the new automation system. Train them on using the automation software, operating the hardware components, and understanding the new processes. Offer ongoing support to address any questions, challenges, or concerns during the transition.

ABOUT US

3S was established as a trusted partner for companies looking to innovate their supply chain through intelligent automated solutions. We are a boutique company specializing in offering a tailored and personalized service, able to accompany clients through every stage of the automation journey, from design to operational management. Our mission is to improve our clients' efficiency and competitiveness by integrating advanced technologies, specialized skills, and a unique consulting approach. Drawing inspiration from global automation leaders, yet offering a tailored and personalized service, we share values such as integrity, collaboration, excellence, and a focus on safety, always placing people and the sustainability of the solutions we offer at the center.

+10

Years of experience

+90

Successful projects

+15

Trained professionals

Reshaping the future of Logistics Automation

Automation creates a new future of sustainability and resilience for the logistics industry, addressing such issues as labor shortages and letting logistics businesses navigate better across the uncertain landscape. The growing demand for personalized logistics automation solutions indicates that the number of logistics automation adopters will keep increasing, gradually eliminating the most pressing issues across the sector.

For more then 10 years, we have been engineering solutions that advance logistics automation. We’re proud to share examples of how we’ve helped our customers maximize performance, advance innovation and drive growth. We hope our customer success stories inspire your business transformation too. Get a Free Audit now.

"At 3S, we embrace innovation and leverage various cutting-edge technologies- such as Augmented Reality (AR) and Artificial Intelligence (AI) to drive Clients operations. With the help of our AR based solutions, for instance our Clients can get real-time information on engine conditions or scan and determine the best configurations of your warehouses, helping them to manage storage space and resources. Thanks to AI based solutions they cut down time wasted on repeatable tasks, saving it for major business needs".

OUR MISSION

To unlock new opportunities for individuals and organizations to tackle today's challenges and shape the future of logistics automation. We are continuously on the lookout for new ways to innovate and push beyond conventional boundaries

OUR VISION

To be the premier technology partner for leading brands and top talent globally, driving exceptional value at the speed of digital

HOW WE WORK

We combine our brught talent with cttuning-edge tecnologies to create solutions that meet emerging productivity standards and exceed market expectations.

Stay competitive in a rapidly evolving digital landscape.

We belive collaboration is a key driver of success in logistics. Establishing strong partnerships with suppliers, carriers, and other stakeholders we streamline operations, share resources, and tap into additional expertise. Together with our Partners we allow businesses to streamline operations, reduce costs, improve efficiency, and enhance customer experience. By leveraging 3S solutions, businesses can stay competitive in a rapidly evolving digital landscape.

As customer demand increases, businesses need to offer faster and more accurate order fulfillment. However, a weak and unorganized inbounding and putaway system can delay fulfilling promises. Efficient warehouse management is critical to a stable supply chain for your e-commerce business. Inaccuracies during inbounding or putaway can cost businesses time, hurt profits, and result in lost customers.

Projecting, implementing and operating logistics automation can be complex. With our expertise in e-commerce logistics and automation, 3S can help you navigate the process, provide tailored solutions, and ensure successful implementation.

If you’re currently in search of such a tech partner for your logistics automation project, get a Free Audit today. Having successfully completed and launched numerous unique logistics automation systems, our consultants and developers will assist you with creating a unique, competitive solution tailored to your specific needs.

Sign up for a "Free audit" and we will get back to you within 24 hours to discuss what services would be best for your business needs. Or speak with us now and tell us what you need.

"At 3S we develop a culture that encourages creativity and empowers our talents to unleash their full potential. By investing in our people, we are able to drive innovation that exceeds our clients’ expectations and helps them discover unconventional ways to achieve their most ambitious goals".

3S Blog